The unobtrusive profile of CastSlot sits neatly within concrete, asphalt, and block surface finishes. CastSlot features an electro painted ductile iron throat section, which is securely fixed to the galvanised steel channel body to provide an exceptionally robust yet discreet drainage system.

A treadsafe option is also available for area where there is regular foot traffic. Available with a 10mm or 30mm opening.

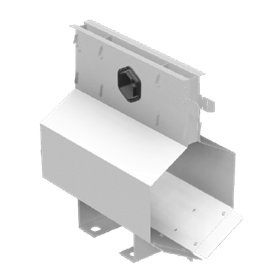

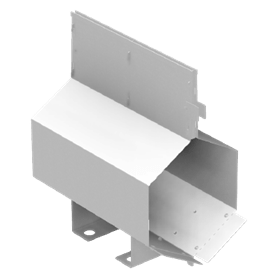

The NEW through spacer gives designers the flexibility to pass cables or other services through the channel throat as well as detail additional reinforcing for CastSlot and UltraSlot products. The new locking design ensures alignment and a tight fit prior to taping and pouring.

CastSlot is ideal for areas of vehicular traffic such as car parks and industrial units where there is slow turning traffic.

Load Classification: A15 to F900

Available channel widths:

High capacity surface water drainage

100mm, 150mm, 225mm, 300mm, 350mm, 400mm, 500mm, 600mm

Performance

- Strong and durable

- Watertight

- Rigid steel lining

- High capacity

- Stepped fall & self-cleansing

- Maximum intake

- Continuous interception(reduced wash-over)

- Fewer channel joints

Installation benefits

- Time and cost savings

- Quick installation

- Easy to handle

- Impact resistant

- High quality finish

Client benefits

- Reduced maintenance cost

- Safe system

- Tamper proof

- No moveable parts

Design benefits

- Simple system, quick design

- Precise and aesthetic

- Design flexibility

- Proven performance

- Quality assurance

Installation benefits

- Time and cost savings

- Quick installation

- Easy to handle

- Impact resistant

- High quality finish

Materials & Finishes

- CastSlot features an electro painted ductile iron throat section, which is securely fixed to the galvanised steel channel body to provide an exceptionally robust yet discreet drainage system.

- Channels should be impact-resistant and manufactured from galvanised sheet steel to BS EN 10346: DX51D+Z275-NA-C.

- Channel material should have 0% water absorption.

- All materials used in manufacture of channel units should be heat resistant and recyclable.

- The manufacturer should ideally operate in accordance with the European Environmental Standard BS EN ISO 14001.

- Channel units should be level invert and supplied in 3.0m, 1.0m or 0.5m lengths